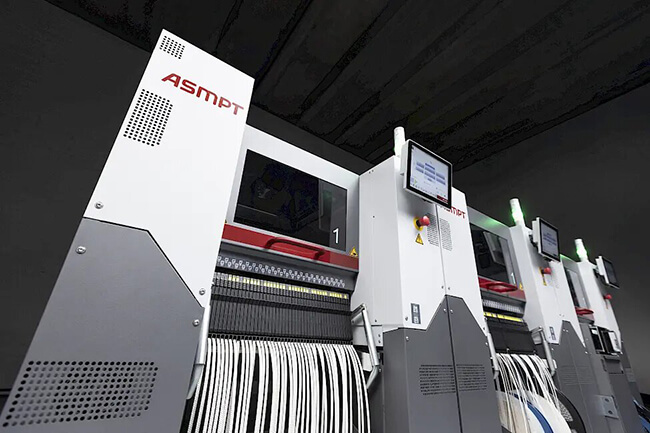

ASM SIPLACE V Pick and place machine

The new era of placement technology

The newly designed SIPLACE V platform combines leading performance, maximum flexibility and highest precision with full compatibility to existing SMT lines.

At the same time, it is consistently designed to meet the requirements of the future – for further automation, efficient big data processing and long-term investment security.

SIPLACE V:

SIPLACE V:

30 % more real performance

The SIPLACE V is a real game changer in terms of performance.

In key industries – from high-mix, low-volume to high-speed production – it achieves a performance increase of up to 30 percent under real production conditions.

This gives electronics manufacturers a clear competitive advantage, especially in the growth markets of the future.

100 % process excellence

No compromises when it comes to quality: The SIPLACE V stands for maximum precision and consistent top performance in every detail.

- Maximum precision: New linear drives and measuring systems with higher resolution for precise placement down to 25 µm @ 3σ.

- Intelligent sensor technology: Closed-loop control adjusts placement force in real time for consistently high quality with every component.

- Perfect alignment: Individually rotatable nozzle segments ensure exact angular positions and error-free placement.

- Automated quality assurance: High-resolution cameras check every component; variable pick-up positions and PCB warping are automatically compensated.

- Seamless traceability: Complete traceability of all components – ideal for automotive applications.

- Process reliability for complex components: Smart Pin Support and improved OSC processing guarantee stable results even with special components.

Unlimited flexibility

Whether it's high speed, mixed placement or special components: The SIPLACE V offers the right solution for all production requirements.

- Comprehensive range of components: From ultra-small 016008M components to large-format odd-shaped components (OSCs), including BGAs.

- Three placement heads for every application: Easy replacement during operation thanks to a new universal head interface.

- Extended feeder capacity: Up to 45 × 8 mm feeders can be used at each location – regardless of options. Supports all SIPLACE X feeders, linear dipping units, power connectors, SIPLACE glue feeders and SIPLACE measuring feeders.

- Flexible transport system: Choice of single or double transport for different PCB sizes and production requirements.

- New Tray Unit V: Slim and space-saving.

- Flexible machine configuration: Choice of single or double gantry version, single or dual conveyor, optional 3D Koplan module and additional cameras.

Ready for the future

Ready for whatever comes next: The SIPLACE V combines today's performance with true future-proofing.

- Open system architecture: Developed from the ground up to be modular and prepared for future pick-and-place head generations and future process requirements.

- High-speed data communication: Gigabit Ethernet for maximum bandwidth, minimal latency, seamless M2M communication and efficient big data management and analysis functions.

- AI and data analysis capable: Integrative data concept creates the basis for AI-supported process optimisation and predictive quality control.

- Automation ready: Already designed for auto-loading feeder, automated feeder change and further automation steps in production.

- Extended platform variants: The SIPLACE V L is a version for large-format PCBs and high components up to 55 mm.

- Seamless software integration: Compatibility with WORKS Software Suite and Factory Solutions from ASMPT

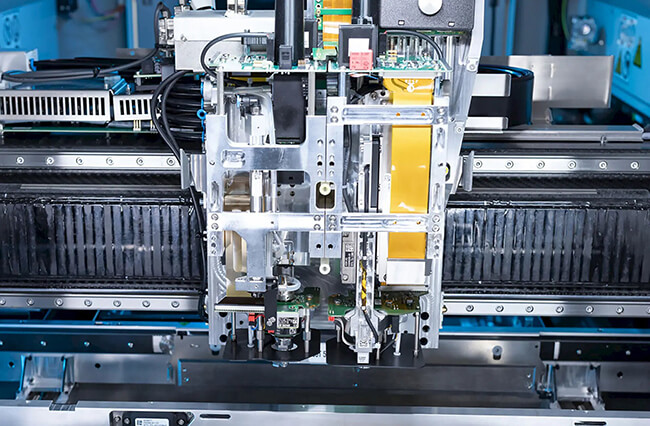

Optimized placement technology

ASMPT has also consistently refined SIPLACE technology in the area of placement heads.

Placement Head CP20

The high-speed collect-and-place placement head with up to 52,500 BE/h at 25 µm @ 3σ precision.

Placement Head CPP

The allrounder for mixed assemblies switches between collect-and-place, pick-and-place or mixed mode via software control.

Placement Head TWIN VHF

The specialist for large and heavy components with up to 100 N placement force for components up to 200 × 150 × 28 mm.

SIPLACE V Boosts Your Intelligent Factory

Setting new standards in placement performance, Flexibility and quality: The SIPLACE V platform is more than just the next generation of placement machines. With significant performance improvements under real production conditions, it gives electronics manufacturing the decisive boost it needs for powerful, future-proof and sustainable intelligent manufacturing.

Highlights

- Up to 30 per cent performance increases in key industries

- Significantly higher performance, even under real production conditions

- Maximum flexibility, even in high-speed applications

- Proven quality assurance features

- Superior performance reserves for future expansions

- Full compatibility with existing ASMPT hardware and software

- Maximum future-proofing and investment security

Options

Placement Head CP20 – for maximum accuracy and speed

- For components ranging from 016008M to 8.2 mm × 8.2 mm × 4 mm (L × W × H)

- Speed: Up to 52,000 cph

- Accuracy: Up to ±25 μm @ 3 σ

- Placement force: 0.5 N to 4.5 N

- Perfect for the fast assembly of standard components at the head of the SMT line

Placement Head CPP – for maximum flexibility

- For components ranging from 01005 to 50.0 mm × 40.0 mm × 15.5 mm (L × W × H)

- Speed: Up to 28,000 cph

- Accuracy: Up to ±25 μm @ 3 σ

- Switches as needed between pick-and-place, collect-and-place and mixed modes

- For perfectly balanced line operation during quick product changeovers with no time-consuming configuration and head changes

Placement Head TWIN – for maximum force

- Places components ranging from 0201 to 200 mm × 150 mm × 25/50 mm (TWIN VHF version) (L × W × H)

- Speed: Up to 6,000 cph

- Accuracy: Up to ±20 μm @ 3 σ

- Placement force: 1.0 N to 100 N (TWIN VHF version)

- Component weight up to 300 g (TWIN VHF version)

- Snap-in detection and 3D measurement in real time

- Perfectly suited for automated end-of-line placement of large and heavy components such as connectors, specialty components, and odd shapes

SIPLACE Measuring Feeder: Precise measurement and verification of components to avoid incorrect placements and improve process reliability

SIPLACE Glue Feeder: Automated application of adhesives for reliable component fixation and improved process reliability

Linear Dipping Unit (LDU): For efficient dipping and placement, also in applications with smaller quantities and multiple dies

SIPLACE Power Connector X: Online power supply with SIPLACE Power Connector X enables feeder preparation or troubleshooting, without stopping the machine

SIPLACE Smart Pin Support: Automated placement of support pins

Tray Unit: Flexible supply system for JEDEC trays

LED Centering: Precise placement of LEDs

OSC Package: Software and hardware solutions for placing large and heavy odd-shaped components

Stationary component cameras: Type 53GigE and type 56GigE

On-board PCB Inspection: Solder paste, pre-placement and post-placement inspection for zero-DPM production

3D Coplanarity Sensor: Detects faulty components for optimal process control

Smart Nozzle Reader: Detects smart nozzles with unique IDs for optimal process control

ASMPT SIPLACE V

Placement speed

105,000 cph

Standard accuracy

±25 µm @ 3σ

PCB dimension (L × W)

up to 850 mm × 610 mm

up to 400 mm × 280 mm Dual-lane mode

up to 700 mm × 530 mm Dual as single

Single-lane mode

to 90 x 8 mm tape feeders

Machine dimensions (L × W × H)

1.1 m × 2.4 m × 1.6 m

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky