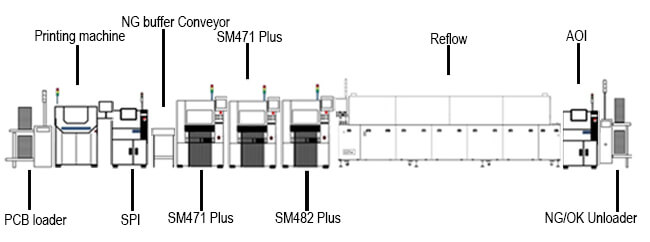

Hanwha SM series high efficiency SMD Full Automatic Assembly line

Hanwha SM series high efficiency SMD Assembly line configuration:

1.Automatic PCB Loader Machine

5.Hanwha SM471 Plus*2 Pick and place machine

6.Hanwha SM481 Plus Pick and place machine

7.Heller 1936 MK7 SMT reflow oven

8.MIRTEC MV-6 Series OMNI 3D AOI

Placement Speed: 186,000 CPH

Accuracy:±50um@μ±3σ

Feeder Capacity(8mm):360ea

Component Range: 0402 ~ 55mm(H 15mm)

PCB size(mm):Max. L460*W400

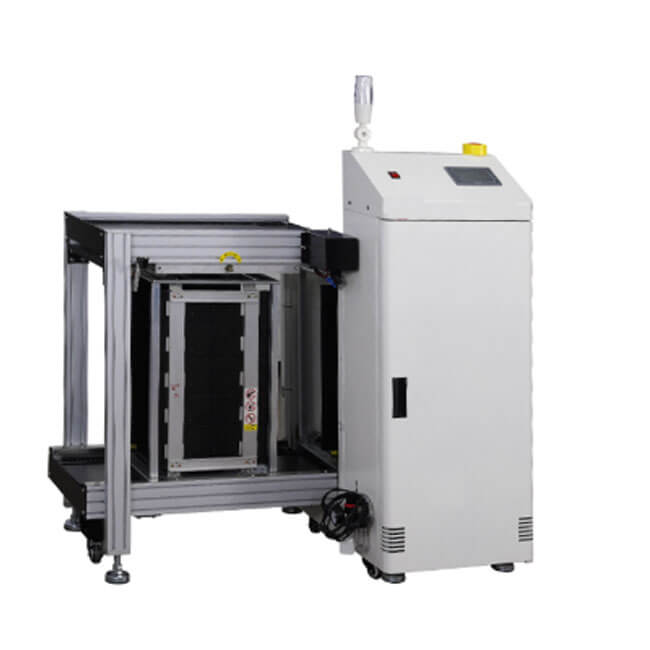

1. Automatic PCB Loader Machine

PCB frame loading machine is a kind of automatic loading equipment for electronic components PCB board. It is usually composed of a conveying system, a positioning system, and an upper plate manipulator.

The working principle is to place the PCB board and component material that need to be mounted on the board in the material frame, and send the material frame to the machine through the conveying system. Then, the positioning system is used to accurately locate the position of the PCB board, and then the components are removed from the material frame by the upper board manipulator and placed on the PCB board accurately.

2. SMT stencil Printer GKG G9+

GKG G9+ SMT Stencil Printer, Fully Automatic tin paste printing machine is a high-end model for SMT high-end application, which can satisfy the printing process requirements of 03015,0.25 pitch, high precision and high speed.

G9+ is high accuracy and high stability of the fully automatic printing machine vision,GKG followed in SMT industry is the development trend of production of a new generation of fully automatic printing machine with the international leading technology synchronous vision, visual processing of high resolution, high precision of the transmission system, suspension adaptive scraper.

Specification :

GKG Series High Precision Automatic Solder Paste Printer designed for high precision

steel mesh printing or stencil printing in SMT industry.

Printing PCB size:50mm x 50mm ~450mm x340mm;

PCB thickness: 0.4mm ~ 6mm

Applicable pitches of Components

SMT Components such as resistors, capacitors, inductors, diode and triode:03015,01005, 0201, 0402, 0603, 0805, 1206 and other specifications;

IC: support SOP, TSOP, TSSOP, QFN packaging, min. pitch 0.25mm; support BGA, CSP packaging,min. ball 0.25um;

Applicable PCB Types

Applicable to PCB types of mobile phone, communication, LCD TV, STB, family cinema, vehicle electronics,

medical power equipment, aerospace and aviation, besides general electronics products.

1,All new 3rd generation stencil X beam structure, add solder paste operators more convenient and accurate placement steel net;

New type torque X beam, solve the solder paste and dust deposition, prolong the service life of the machine;

2,Scalable on pressure device, in view of easy deformation of the PCB printing can make the tablet out, don't need to use pressure

for a little while can back again. According to the product flexible use

3,The whole machine use imported self-lubricating guide rail, guide rail need not add lubricant, within five years guide free maintenance within five years.

4,X Y1 Y2 in U.S. HAYDON linear motor, the Japanese precision drive screw, self-lubricating guide rail, to ensure accuracy

5,Net frame Y to automatically locate, can quickly realize automatic stencil counterpoint;

6,Curved blade beam using high strength steel, in the printing process to ensure the stability of the print head;

Floating type scraper system, the unique elastic stay device, can very good protection in scraper drop process stencil and scraper.

The MS-11 In-Line SPI System uses Shadow Free Moiré Phase Shift Imaging Technology to inspect solder paste deposition on PCBs post screen printing. The MS-11 will inspect for; insufficient solder, excessive solder, shape deformity, shift of deposition and bridging. The MS-11 is configured with a 10M pixel or the 15M pixel ISIS Vision System for enhanced image quality, superior accuracy and lightening fast inspection rates. The MS-11 uses the same robust platform as MIRTEC’s MV-7 Series. Inspection heads are interchangeable between the two systems, adding ultimate flexibility to the inspection process.

MS-11 SeriesOutstanding performance at resonable price

Outstanding performance

- Super high resolution CXP camera and precision 6㎛ lens

- Solder paste inspection up to 0201(㎜) size component pad

- High accuracy & repeatability

- Shadow-free dual projection 3D measurement

- Various camera line-up from high-performance 25 mega pixel to economical 4 mega pixel

Auto PCB warpage compensation

Closed-Loop System : Optimize the manufacturing process by connection with Screen Printer and Pick & Place Machine

Intellisys® : Total process management system for improving productivity and achieving smart factory

Standard 3D AOI for various manuracturing process

4. SMT NG buffer Conveyor

● Exterior structure: plate gold structure and aluminum profile into the frame, the surface spray treatment and the color is wavy white.

● Microcomputer PLC control system works stably and reliably.

● Operating by touch screen, with automatic fault diagnosis function, convenient man-machine dialogue.

● Multiple sound and light and touch screen inside prompt alarm function.

● Using stepper motor to transmission.

● The bad board can be stored 10 pcs by rising and the good boards can be directly transported to the next machine.

● Applicable behind AOI and SPI devices.

● Double line number to distinguish NG\OK.

5. Hanwha SM471 Plus Pick and place machine

The Hanwha SM471 PLUS is a high performance chip shooter which applies two gantries equipped with 10 spindles per head as well as a new Fly Camera system.

Compared to the existing SM471 model, its placement speed is increased further to 78,000CPH, which is the highest in the world among chip shooters of the same class. In addition, it is basically applicable to components from 0402 (01005inch) chips to maximum □14mm IC components. Its actual productivity and placement quality is improved by applying high-speed and high precision electrical feeders. With two gantries and dual lane, the SM471PLUS supports various production modes to maximize the productivity of SM series machines.

6. Hanwha SM481 Plus Pick and place machine

Features: New flying head structure and optimization of suction/placement actions for 10 Spindles

• Highest placement speed in its real class

• Placement accuracy correction system (suction position correction, head correction, track correction, etc.)

• Can mount 0402~□16mm (H=10mm), for the production of long boards for LEDs and displays

• Compatible with MAX.740(L)×460(W) PCB (option)

• NEW The vacuum system and suction/placement mode are optimized, and the function of automatic alignment of the suction position

• Through the vacuum pump, the suction is stable and the consumption of air pressure is minimized

• Applicable to electric feeder, improving actual productivity and placement quality

• And it can be shared with SM pneumatic feeder to solve customer's convenience

• Parameters: Up to 120 8mm feeders (Docking Cart) can be accommodated

10 Shaft*1 Cantilever

• Mounting speed: 40,000CPH (excellent conditions)

• Mounting accuracy: ±50um@u+3ò/Chip, ±30um@u+3ò/QFP

• Component size: Chip 0402~ 16mm IC(H 10mm)

• Substrate size (single rail): 50(L)*40(W)~460(L)*400(W)

• PCB thickness: 0.38mm~4.2mm

• Power supply: AC200/208/220/240/380/415V(50/60Hz,3Phase)Max.4.7kva

• Air pressure: 0.5~0.7Mpa (5-7kgf/c㎡) 160nl/min

• Weight: about 1655KG

• Equipment size: 1650(L)*1680(D)*1530(H)

7. Heller 1936 MK7 SMT reflow oven

The 1936 MK7 is a high volume reflow oven system with 10 heated zones and belt speeds up to 1.88m/min. The 1936 MK7 offers the lowest delta T’s, reduced nitrogen and electrical consumption and advanced flux management options. The 12” wide heater modules offer profile compatibility with competitor systems.

Built-in Thermal Monitoring

Nitrogen Capable to < 100 ppm

Energy Management System

Virtually No Maintenance

12” Wide Heater Modules

8. MIRTEC MV-6 Series OMNI 3D AOI

The MV-6 OMNI Series by MIRTECH is an Automated Optical Inspection Machine that is suitable for inspecting PCBs with an optimal size of 480 x 460 mm. It can inspect components with sizes ranging from 0402 to 01005. This AOI uses a dual camera system of 15 and 25 megapixels and the resolution ranges from 10 µm to 15 µm. It has a wide field of view of 58.56 x 58.56 mm which is achieved by an 8-phase Colour Lighting System to deliver clear and detailed images for the inspection of PCBs. This machine has an inspection speed of around 0.77 sec/FOV, and easy movement of the camera is maintained by providing Top and Bottom clearance of around 45 mm and 50.8 mm respectively.

The MV-6 OMNI series can detect PCB defects like missing parts, wrong parts, misalignment, skew, polarity, and tombstones. It features non-blind spot digital 12 projection moiré 3D inspection technology for meticulous examination of reflective objects, OCR, and crack defects through its 8-phase coaxial colour light setup. The side-viewer feature allows simultaneous 5-dimensional inspection using 18-megapixel angled cameras, while Intellisys serves as a comprehensive process management system for optimizing productivity and realizing smart factory goals. Additionally, its AI Auto Programming simplifies the programming process using IPC international standard libraries, all offered at a compelling and competitive price point.

9. SMT NG/OK Unloader Machine

According to signal recognition, NG board and OK board are automatically collected into two lifting turnover boxes respectively; The NG\OK receiver is connected with AOI, after AOI detection to determine the good (OK) and bad (NG) output different signals, the signal is transmitted to the next NG\OK receiver, the NG\OK receiver receives the signal sent by AOI for judgment, and the PCB is automatically classified and stored in the OK and NG material frame; Such as: AOI output OK signal through NG\OK judgment into the moving trolley directly into the OK lifting trolley material frame; The AOI output NG signal is judged by NG\OK into the moving car and transferred to the material frame of the NG lifting car at the back.

Appearance structure :3mm thick sheet metal structure and aluminum profiles into the frame, surface spray treatment, color is corrugated white.

Microcomputer original Panasonic PLC control system, stable and reliable work.

Touch screen display operation, with automatic fault diagnosis function, man-machine dialogue is convenient.

Multiple sound, light and touch screen prompt alarm function.

The lifting step of the rack can be set according to the PCB thickness.

With automatic counting function, convenient production statistics.

Humanized design ensures that the PCB board is not broken and improves the output capacity

The bottom connecting PCB board uses a motor to push the board into the material frame

Stepper motor push plate, strength, speed can be set on the touch screen,

The push-plate device uses the Omron groove sensor to protect the PCB board from being pushed out

Push the PCB board can set the push distance in the touch screen

The OK plate is loaded into the front material frame, and the NG plate is loaded into the fabric frame.

Double line number distinguish NG\OK

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky