JUKI JM-100 Full Automatic THT line

Configuration:

1.PCB Loader

2.JUKI JM-100 Automatic Insertion Machine

3.Wave Solder Infeed conveyor

4.ERSA VERSAFLOW 3/45 Selective Soldering Machine

5.Wave Soldering outfeed conveyor

6.PARMI Bottom Side Inspection 3D AOI

7.NG/OK Unloader

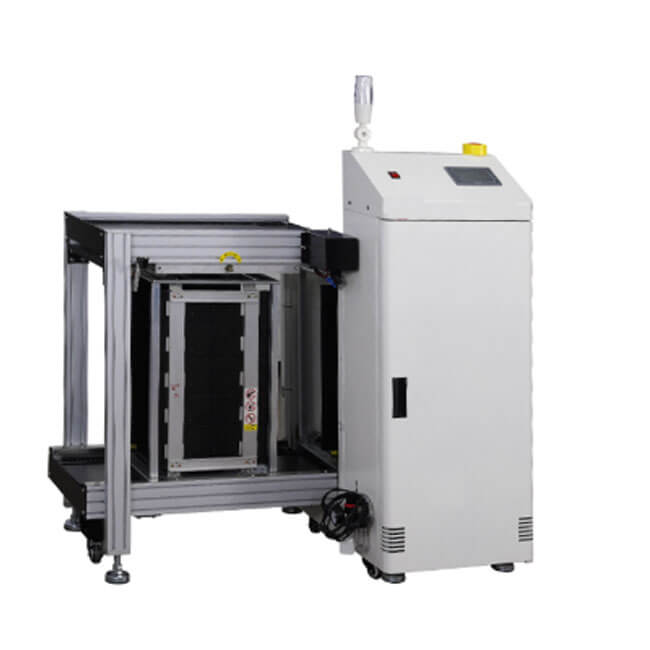

1. PCB loader

PCB frame loading machine is a kind of automatic loading equipment for electronic components PCB board. It is usually composed of a conveying system, a positioning system, and an upper plate manipulator.

The working principle is to place the PCB board and component material that need to be mounted on the board in the material frame, and send the material frame to the machine through the conveying system. Then, the positioning system is used to accurately locate the position of the PCB board, and then the components are removed from the material frame by the upper board manipulator and placed on the PCB board accurately.

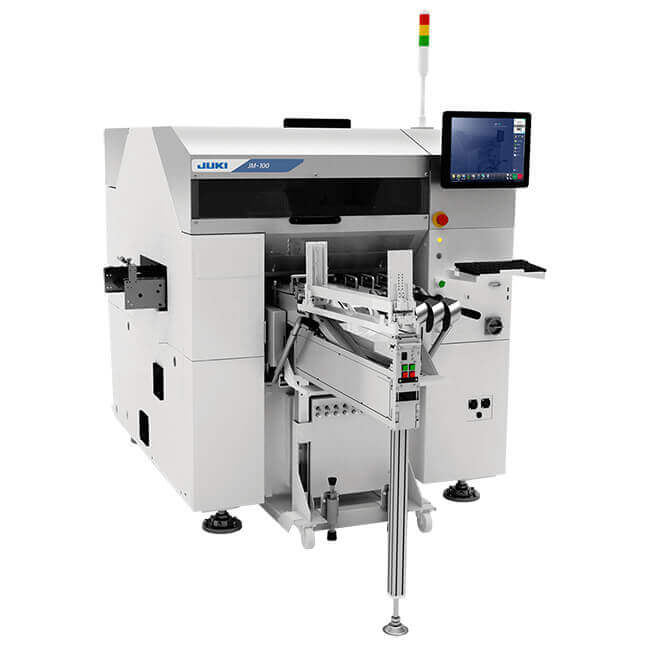

2. JUKI JM-100 Automatic Insertion Machine

The new JM-100 utilizes Juki’s advanced TAKUMI placement head. This head automatically adjusts it’s height to provide the optimal speed and component handling at the same time. It can pick with up to 8 nozzles at the same time, as compared to the JM-10’s 6 nozzles. The result of these improvements is up to 38% faster insertion time. The TAKUMI head also supports larger and taller components than the previous design.

New options increase the JM-100’s flexibility and capability even further. A clinching unit provides active clinching for a variety of lead sizes and patterns. A new 3D image recognition sensor provides fast and accurate centering of even complicated lead patterns and shapes.

The JM-100 is supported in Juki’s JaNets line control software, along with all other current pick and place models. This makes it easy to program the entire line from one software package.

As a leading company in post-process automation, JUKI is working to develop more automated manual insertion processes for customers. We will continue to offer equipment based on ‘JUKI Smart Solutions‘ to increase productivity, automation, labor saving, and efficiencies of the entire packaging factory, and support our customers.

Feature

Equipped with new “Takumi-Head”. Higher speed and wider component range

Vacuum nozzle insertion time is reduced from 0.8 sec to 0.6 sec (25% faster). Gripper nozzle insertion time is reduced from 1.3 seconds to 0.8 seconds (38% faster). Overall best tact time in class.

In addition, the maximum part size and height that can be handled have also been greatly expanded.

New Clinch Unit to Improve Production Efficiency and Quality

The new active clinch unit option provides greater production flexibility for cases where components have a risk of bouncing out of the PCB. Different clinching patterns are possible including inner bend, outer bend, and N shape bend.

3D Image Recognition Option for High-precision Insertion of a Wide-range of Parts

The 3D recognition option uses a phase-shifting technique to measure the entire component quickly and accurately, including the lead tip. This sensor works well even for low reflectivity components and ones with a wide height range.

Wide variety of nozzles and feeders

Many different feeder types are available for taped, tube, bulk, and tray components. Many standard and custom nozzles make it possible to pick a variety of odd-form components.

JaNets Line Control Software

Juki’s JaNets line control software is compatible with the JM-100. This makes it easier for programmers to prepare files for both the SMT and odd-form machines at the same time.

3.Wave Solder Infeed conveyor

Wave solder infeed conveyor, it is used to feed PCB’s or pallets into wave soldering machine at 6-7°. conveyor width and angle can be adjusted by hand crank. Special belt and track, transmission smooth, and work stable and reliable.

- Demensions(L×W×H): 1000*700*750(mm)- PCB width: 0-350(mm)

- PCB direction: L-R

- Conveyor speed: 0-2000(mm)/Min

- Motor: 1P AC220V 50/60HZ 15W

- Conveyor Height: 750±20mm

- Belt Material: ESD Belt

- Conveyor length: 1000(mm)

- Lead time: 15 days

4.ERSA VERSAFLOW 3/45 Selective Soldering Machine

The first inline selective system with double transport Tech-Highlights VERSAFLOW 3/45

- Highest throughput in the entire selective soldering market

- Most sold selective machine platform worldwide

- Safe process control with monitoring of all relevant parameters

- Full modularity - suitable for every customer requirement

- Ersa selective soldering with the world´s most successful inline selective soldering machine VERSAFLOW 3/45

5. Wave Soldering outfeed conveyor

1、Sheet metal + 40 * 40 iron square welding powder coating processing structure, stable, strong, durable.

2、Three sets of 15W speed control motors are used, which are stable and reliable.

3、Divided into three sections of transmission, the first section for parallel transmission, the second section for slope transmission, the third section for parallel transmission.

4、Using anti-slip belt and silicone chain to transmit three groups of motors to control the transmission independently.

5、Using special aluminum machined parts to make guide rail and adjust the width at the same time.

6、Using metal conveyor wheels and imported STK bearings.

7、Width adjustment over the board size 80-400mm.

8、Machine body size 1500*600mm

9、Board In Height: 900-1200mm adjustable

10、Board Out Height: 900-1200mm adjustable

11、Adjustment of lifting height adopts 20mm standard screw + nut.

12、Can stop 3 pieces of boards

13、Standard with SMEMA communication signal line

6. PARMI Bottom Side Inspection 3D AOI

PARMI Bottom Side Inspection 3D AOI

The Xceed BSI from PARMI is a specialized 3D AOI machine designed for bottom side inspection of PCBs, particularly after wave or selective soldering processes. This innovative system eliminates the need for flipping the PCB, thus reducing handling risks and minimizing the production line footprint. It’s adept at inspecting THD (Through-Hole Device) pin positions and heights, solder joints, and general SMD (Surface-Mount Device) components on the bottom side of PCBs.

Key Features

3D AOI for Bottom Side Inspection: Specifically designed for inspecting the underside of PCBs without flipping, enhancing efficiency and safety.

Space-Saving Design: Eliminates the need for a PCB flip unit, reducing the required footprint in the production line.

Comprehensive Inspection Functions: Includes inspection of wave or selective soldering, THD pin position and height, solder joint inspection (insufficient, excessive, bridging, etc.), and full inspection of mixed technology PCBs (SMD & THD).

Accurate Solder Joint Inspection: Utilizes a highly focused laser beam for precise measurement of mirror-like solder joints, ensuring accurate defect detection without false calls.

Dual Laser Technology: Provides the capability to inspect components and pins up to 35mm high with the same precision as small components.

Consistent Software Environment: Uses the same software and algorithms as the standard Xceed machine, allowing for consistent programming across SMD inspection processes.

7. NGOK Unloader Machine

According to signal recognition, NG board and OK board are automatically collected into two lifting turnover boxes respectively; The NG\OK receiver is connected with AOI, after AOI detection to determine the good (OK) and bad (NG) output different signals, the signal is transmitted to the next NG\OK receiver, the NG\OK receiver receives the signal sent by AOI for judgment, and the PCB is automatically classified and stored in the OK and NG material frame; Such as: AOI output OK signal through NG\OK judgment into the moving trolley directly into the OK lifting trolley material frame; The AOI output NG signal is judged by NG\OK into the moving car and transferred to the material frame of the NG lifting car at the back.

Appearance structure :3mm thick sheet metal structure and aluminum profiles into the frame, surface spray treatment, color is corrugated white.

Microcomputer original Panasonic PLC control system, stable and reliable work.

Touch screen display operation, with automatic fault diagnosis function, man-machine dialogue is convenient.

Multiple sound, light and touch screen prompt alarm function.

The lifting step of the rack can be set according to the PCB thickness.

With automatic counting function, convenient production statistics.

Humanized design ensures that the PCB board is not broken and improves the output capacity

The bottom connecting PCB board uses a motor to push the board into the material frame

Stepper motor push plate, strength, speed can be set on the touch screen,

The push-plate device uses the Omron groove sensor to protect the PCB board from being pushed out

Push the PCB board can set the push distance in the touch screen

The OK plate is loaded into the front material frame, and the NG plate is loaded into the fabric frame.

Double line number distinguish NG\OK

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky