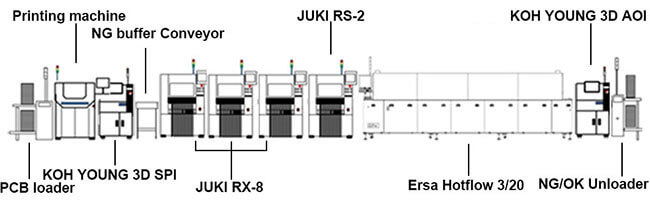

JUKI RX-8 SMT Assembly line

JUKI RX-8 SMT Assembly line configuration:

1.Automatic PCB Loader Machine

2.SMT Stencil Printer DEK NeoHorizon 03iX

5.JUKI RX-8 *3 Pick and place machine

6.JUKI RS-2 Pick and place machine

7.ERSA HOTFLOW 3/20 Reflow Soldering

Placement Speed: 350,000 CPH

Accuracy:±40 μm @ Cpk ≥ 1.0

Feeder Capacity(8mm): 280ea

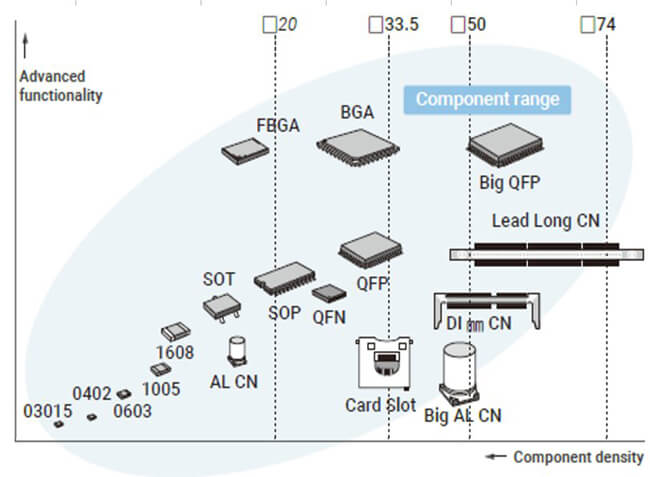

Component Range: 0201 ~ □50 mm x 150 mm (1 x 3 segment recognition) x □74mm (2 x 2 segment recognition)

PCB size(mm):Max. L510*W370

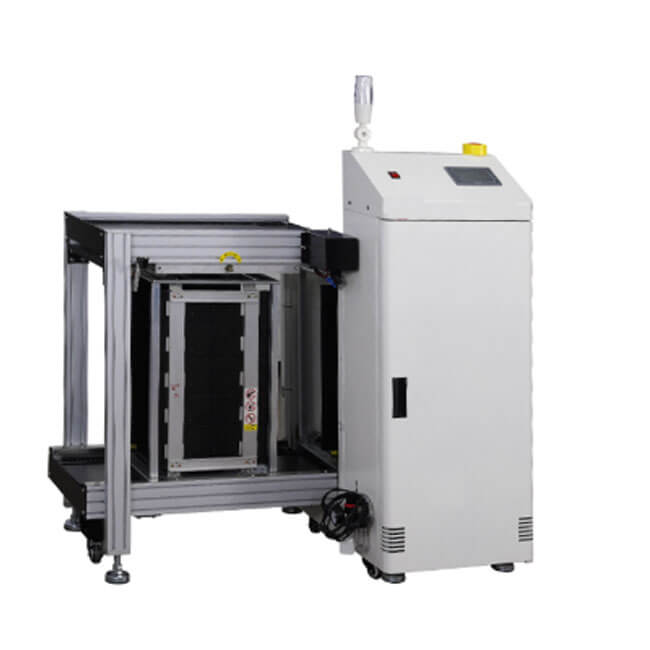

1. Automatic PCB Loader Machine

PCB frame loading machine is a kind of automatic loading equipment for electronic components PCB board. It is usually composed of a conveying system, a positioning system, and an upper plate manipulator.

The working principle is to place the PCB board and component material that need to be mounted on the board in the material frame, and send the material frame to the machine through the conveying system. Then, the positioning system is used to accurately locate the position of the PCB board, and then the components are removed from the material frame by the upper board manipulator and placed on the PCB board accurately.

2. SMT Stencil Printer DEK NeoHorizon 03iX

DEK NeoHorizon Solder paste printer

Maximum flexibility for the integrated smart factory

With its modular and scalable configuration options, the DEK NeoHorizon printer meets any process requirements and offers best flexibility for any production volumes

DEK NeoHorizon Innovations

Best printing offering to cover all your needs

DEK NeoHorizon 03 iX:

Machine Alignment Capability: ±12.5 µm @ 2.0 cmk, (±6 Sigma)

System Alignment Capability: +/- 20μm @ 2.0 cmk, (±6 Sigma)

Wet Print Capability: ±25 µm @ 2.0 cpk, (±6 Sigma) - Certified by external system for every printer before delivery by standard

Core Cycle Time (CCT): 8 sec.

Perfect printing solution for best performance in high-mix production

DEK NeoHorizon 01 iX:

Machine Alignment Capability: ±12.5 µm @ 2.0 cmk, (±6 Sigma)

System Alignment Capability: +/- 15μm @ 2.0 cmk, (±6 Sigma)

Wet Print Capability: ±20 µm @ 2.0 cpk, (±6 Sigma) - Certified by external system for every printer before delivery by standard

Core Cycle Time (CCT): 6.5 sec.

Best printing quality with maximum throughput

DEK NeoHorizon Back-to-Back:

The DEK NeoHorizon Back-to-Back setup offers higher print performance in dual-lane assembly line.

DEK NeoHorizon Options

DEK provides the industry’s most powerful and flexible printing platforms. The following retrofittable DEK options help you further improve productivity and print quality on your DEK NeoHorizon printer:

1.Full flexible DEK All Purpose Clamping (APC) system

2.High flexibility and maximum cleaning performance with DEK Typhoon Cleaner

3.DEK Grid-Lok: the universal board support system

4.DEK Paste Management: the best combination of automated paste dispensing with paste roll height control

5.Closed loop to SPI systems with ProDEK

6.DEK Multiple Alignment of Singulated Substrates (MASS) offers a solution for individual optical alignment at a very high speed to boost your throughput

World-Fastest Full 3D Solder Paste Inspection

The industry’s fastest full 3D measuring inspection solution- Solves shadow problems by utilizing 2-way projection- Full 3D foreign material inspection for the entire PCB- Provides accurate inspection data with real-time PCB warp compensation·Full 3D data-based process optimization solution: Realization of industry 4.0 / smart factory- Realizes real-time process optimization through powerful SPC analytics- Provides a powerful printing process optimization tool·Leading model for high-speed mass production line

● Exterior structure: plate gold structure and aluminum profile into the frame, the surface spray treatment and the color is wavy white.

● Microcomputer PLC control system works stably and reliably.

● Operating by touch screen, with automatic fault diagnosis function, convenient man-machine dialogue.

● Multiple sound and light and touch screen inside prompt alarm function.

● Using stepper motor to transmission.

● The bad board can be stored 10 pcs by rising and the good boards can be directly transported to the next machine.

● Applicable behind AOI and SPI devices.

● Double line number to distinguish NG\OK.

5. JUKI RX-8 *3 Pick and place machine

- High-speed placements of up to 100,000 CPH.

- Best-in-class placement rate per square meter(sq ft).

- Integrates seamlessly with the production enviroment

- Trace Monitor tracks quality throughout production process

- Low impact placement for flexible circuits

- The P20 high-precision planet head is ideal for high speed pocking and placing from a single reel.

- State-of-the-art centering and inspection vision system

- New high accuracy camera for inspection and centering

6. JUKI RS-2 Pick and place machine

High speed of 50,000CPH

By positioning the laser sensor closer to the board and reducing travel time from pick-up to placement, the one-head mounter achieves an optimal speed of 50,000 CPH in its ideal conditions.

*Optimum condition

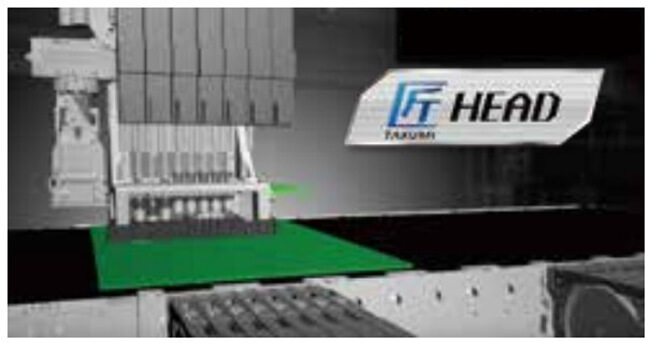

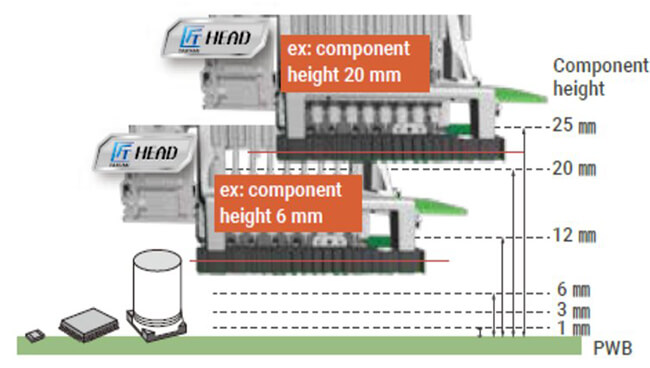

“TAKUMI Head” with adaptive sensor height

The height of the laser sensor on the “TAKUMI Head” automatically adjusts based on the height of each component being placed,

allowing precise pick-up and placement.

This 8-nozzle “TAKUMI Head” accommodates components of varying heights, from the smallest to the largest, ensuring optimal

speed and accuracy.

Component height can be selected from six levels: 1, 3, 6, 12, 20, and 25 mm.

“TAKUMI Head” which changes with the height of the sensor

Realizes high-speed, high-precision recognition with JUKI’s proud laser-recognition technique

JUKI’s laser-recognition technology enables fast, accurate identification of various component shapes, including BGA, SOP, and QFP, ranging from as small as 03015 to sizes up to 50 mm square. This laser-recognition system ensures stable recognition and placement, unaffected by variations in electrode shape or surface gloss. Additionally, creating component data is simplified, allowing for quick integration of new components.

Flexibility

Wide component range

Supports components from sizes as small as 03015 up to 74 mm square or 50 mm x 150 mm, with placement heights accommodating components up to 25 mm.

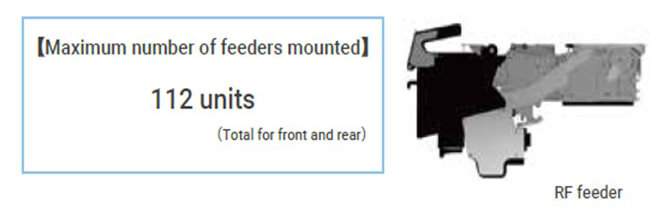

Up to 112 feeder mounting for flexible and efficient production

Up to 112 feeder mounting for flexible and efficient production

The compact, lightweight, and slim design of the RF feeder supports up to 112 feeder units (front and rear combined),

enabling high-efficiency production.

This setup is ideal for multi-product, small-lot production with minimized setup times.

* When RF feeder (RF08AS) is used.

Quality

Quality

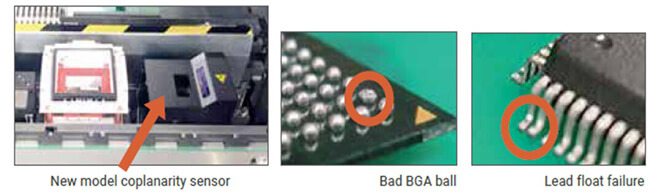

NEW Advanced high-precision coplanarity new model

Detects lead floating and BGA ball deformation to prevent the placement of defective components. High-precision coplanarity checks enhance product reliability.

7. ERSA HOTFLOW 3/20 Reflow Soldering

The Ersa HOTFLOW 3/20 Reflow Soldering System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

Excellent heat transfer with the most varied board assemblies

Rest-oxygen monitoring and control with low N2 consumption

Low energy consumption through intelligent energy management

Multi-level controlled cooling

Multi-level process gas cleaning system

"On the fly" maintenance for increased machine availability / uptime

Multi-track conveyor system (1-4 tracks)

Ersa Process Control (EPC) for continuous process monitoring

Ersa Auto Profiler software for quickly generating temperature profiles

Options:

Multi-track conveyor system with separate drives each track

Connectable center supports

Inert atmosphere feature with rest-oxygen monitoring and control

Metering of N2 consumption

Power-cooling with 3 convection modules and "on the fly" process gas cleaning

Emergency power supply

Ersa Process Control (EPC)

Auto Profiler

Computation of energy consumption

Quick profile change

Up to 4 tracks with center support can be installed (1 track fixed, 3 tracks movable) - increasing the flexibility of the system

8. KOH YOUNG ZENITH 3D AOI

Ultimate Solution for Inspection Challenges

Circuit boards are becoming more complex with new products. An AOI machine is becoming even more crucial to the electronics manufacturing lines. The industry has many2D, 2.5D and pseudo-3D inspection options that only compound issues with false calls and escapes. The Zenith AOI Series is the only machine that delivers True 3D Inspection to address solutions caused by highly specular packages and shadows from adjacent parts.

Incomparable True 3D Inspection Performance

The Zenith AOI Series is the only solution in the industry to base its inspection criteria according to IPC-610 standards for electronic assembly acceptability requirements. It provides clear and precise AOI measurements to accurately identify multiple defects such as missing solder, offset, polarity, upside down, OCV/OCR, solder fillet, billboarding, lifted lead, lifted body, tombstone, bridging, and more. Because it uses a quantitative True 3D measurement-based approach, the system delivers exceptional accuracy and repeatability.

IPC-based Solder Joint Inspection

Through Koh Young’s proprietary vison algorithms, the Zenith Series can quantify the exact height of a solder joint. Despite shadows or interreflection challenges, the Zenith accurately inspects and measures according to IPC-610 standards for electronic assembly acceptability requirements.

AI-Powered Auto Programming (KAP)

Industry-leading 3D profilometry technology converges with Koh Young’s proprietary AI technology to deliver true automatic programming. The innovative geometry-based Koh Young Auto Programming (KAP) software solution reduces the programming process to minimizes time to production and reduces costs.

KSMART Solutions: True 3D Measurement-based Process Control System

Koh Young pioneered True 3D measurement technology 20 years ago to create a zero-defect

9. SMT NG/OK Unloader Machine

According to signal recognition, NG board and OK board are automatically collected into two lifting turnover boxes respectively; The NG\OK receiver is connected with AOI, after AOI detection to determine the good (OK) and bad (NG) output different signals, the signal is transmitted to the next NG\OK receiver, the NG\OK receiver receives the signal sent by AOI for judgment, and the PCB is automatically classified and stored in the OK and NG material frame; Such as: AOI output OK signal through NG\OK judgment into the moving trolley directly into the OK lifting trolley material frame; The AOI output NG signal is judged by NG\OK into the moving car and transferred to the material frame of the NG lifting car at the back.

Appearance structure :3mm thick sheet metal structure and aluminum profiles into the frame, surface spray treatment, color is corrugated white.

Microcomputer original Panasonic PLC control system, stable and reliable work.

Touch screen display operation, with automatic fault diagnosis function, man-machine dialogue is convenient.

Multiple sound, light and touch screen prompt alarm function.

The lifting step of the rack can be set according to the PCB thickness.

With automatic counting function, convenient production statistics.

Humanized design ensures that the PCB board is not broken and improves the output capacity

The bottom connecting PCB board uses a motor to push the board into the material frame

Stepper motor push plate, strength, speed can be set on the touch screen,

The push-plate device uses the Omron groove sensor to protect the PCB board from being pushed out

Push the PCB board can set the push distance in the touch screen

The OK plate is loaded into the front material frame, and the NG plate is loaded into the fabric frame.

Double line number distinguish NG\OK

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky