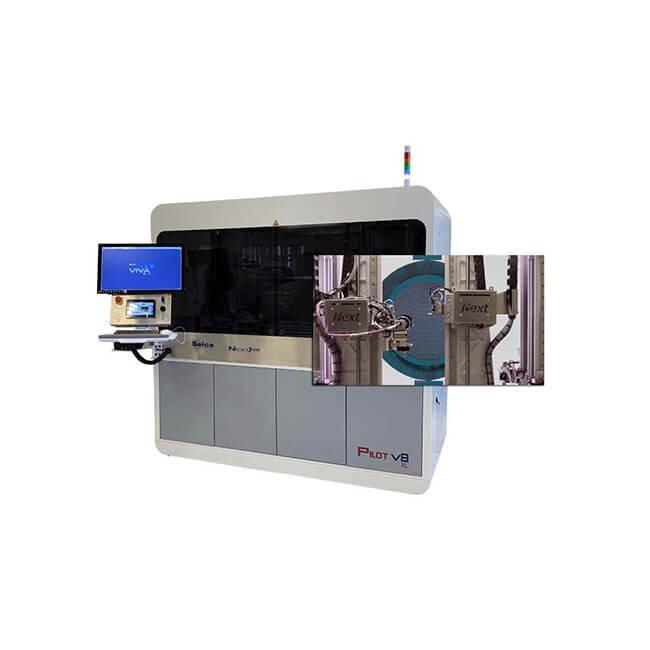

Pilot V8 HR flying needle online measurement vertical double-sided 8-pin

Guckless technology for challenging probe cards Wafer fabrication is a step-by-step process that gradually forms electronic circuits. By way of simplification, during the fabrication of a silicon wafer, some integrated circuits are placed on a semiconductor wafer. The wafer is then diced and packaged. Before cutting, the circuit needs to be tested. This electrical test is carried out with the help of a probe card.

Product Description

Guckless technology for challenging probe cards

Wafer fabrication is a step-by-step process that gradually forms electronic circuits.

By way of simplification, during the fabrication of a silicon wafer, some integrated circuits are placed on a semiconductor wafer. The wafer is then diced and packaged. Before cutting, the circuit needs to be tested. This electrical test is carried out with the help of a probe card.

What is a probe card?

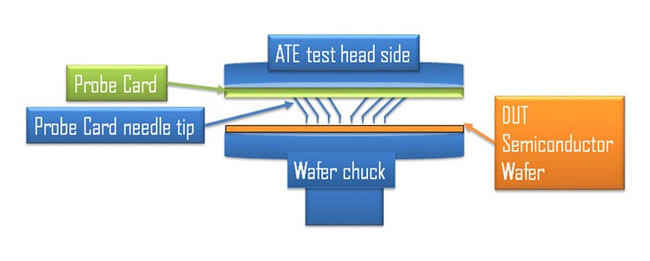

A probe card is generally an interface that provides electrical and mechanical connections between the device under test (I. e., the semiconductor wafer) and the test system electronics.

The probe card consists of the following elements

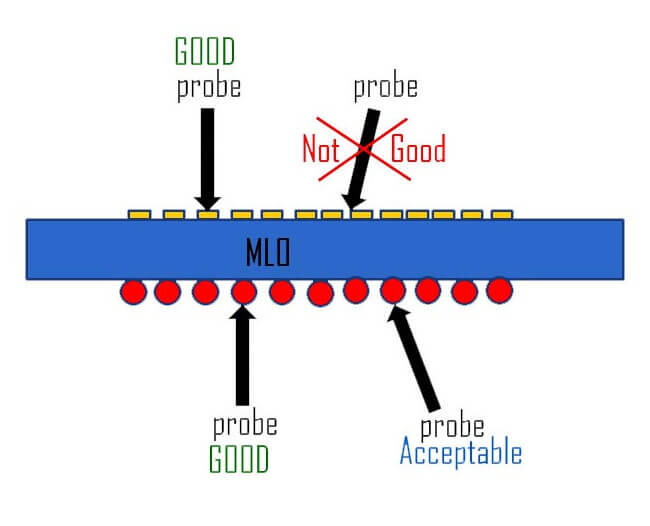

Multi-layer organic substrate (MLO)

· PCB Board

The wafer test system consists of different parts:

· The wafer under test [DUT] is distributed on the wafer chuck

The probe card is mounted on the wafer as a connector between the wafer pads and the test system.

How to test the probe card?

So far, we have seen that the probe card is part of the wafer test system, but before integrating it into the wafer test system, the probe card must be tested. Due to the increase in equipment I/O bandwidth and power requirements, high-performance power and signal transmission requirements must be met during electrical testing. These requirements create challenges for the testing of probe cards.

With years of experience in probe card testing, Seica has designed and launched the Pilot V8XL HR Next series, a flying needle tester that provides a complete one-stop solution for probe card testing.

The Pilot V8 XL HR Next series integrates three different tools in a unique system to perform:

· Single MLO™and PCB light board test

· Assembled PCB board ICT and functional carrier board test

· PCB MLO™Probe Card Testing

ICCT (Conduction Integrity Certification Test): as a certification of the integrity of the connection between the MLO and the PCB

Key hardware features of the Pilot V8 XL HR Next series:

Vertical platform (easy to load, can also load round plate)

· 8 completely independent test probes

Front: 2 standard probes 2 HR probes

Back: 4 standard probes

Large test area 800x650mm

· Full plate warpage control laser sensor

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky