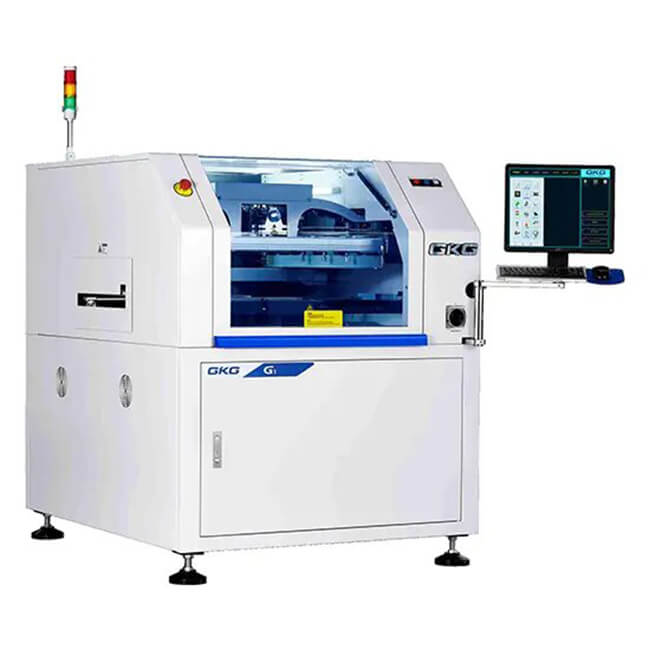

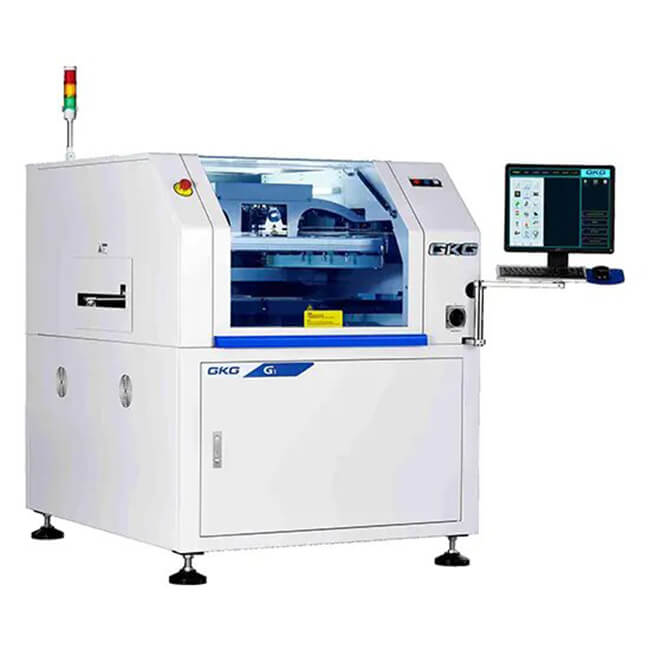

SMT stencil Printer GKG G5

GKG G5 is a high-precision and high-stability fully automatic visual printing machine, high-resolution visual processing, high-precision transmission system, suspended automatic adaptive scraper, precise board positioning processing and smart screen frame clamping structure, compact structure , both accuracy and high flexibility, precise printing required functions.

1. GKG dedicated manual adjustment pre-lift platform: simple and reliable structure, low cost, convenient manual adjustment, can quickly realize the adjustment of the PIN pin jacking height of PCB boards with different thicknesses.

2. Image and optical path system: The uniform ring light and high-brightness coaxial light of the brand-new optical path system, together with the brightness function that can be adjusted steplessly, make all types of Mark points can be well recognized (including uneven ones) Mark point), suitable for tin-plated, copper-plated, gold-plated, HASL, FPC and other types of PCBs of different colors.

3. Scraper system: Slide rail type scraper system, which improves the running stability and long service life.

4. Cleaning system: The new type of wiping rubber strip ensures full contact with the stencil, increases the vacuum suction to ensure that the residual solder paste in the mesh is vigorously eliminated, and truly realizes the effective automatic cleaning function, three cleaning modes of dry and wet vacuum , the software can set the cleaning mode and cleaning paper length at will.

Machine performance

Repeat position accuracy

±0.01mm

Print accuracy

±0.025mm

NCP-CT

7.5s

HCP-CT

19s/pcs

Process CT

5min

Change line CT

3min

Substrate processing parameter

Max board size

400*340mm (Option:530*340mm)

Min board size

50*50mm

Board thickness

0.4~6mm

Camera mechanical range

528*340mm

Max board weight

3kg

Board adge clearance

2.5mm

Board height

15mm

Transport speed

900±40mm

(Max) Transport speed

1500mm/s max

Transport direction

One stage

Transmission direction

Left to right

Right to left

In and out the same

Support system

Magnetic pin

Support block

Manual up-down table

Board damp

Automatic the top clamping

Side clamping

Adsorption function

Printing parameters

Print speed

10-200mm/s

Printing pressure

0.5~10kg

Print mode

One/twice

Queegee type

Rubber, squeegee blade (angle 45/55/60)

Snap- off

0-20mm

Sanp speed

0-20mm/s

The template frame size

470*370mm-737*737mm (thickness 20-40mm)

Positioning mode of steel mesh

Automatic Y-direction positioning

Cleaning parameteres

Cleaning method

Dry, wet, vaccum, three modes

Cleaning system

Up drip type

Cleaning stroke

Automatic generation

Cleaning position

Post cleaning

Cleaning speed

10-200mm/s

Cleaning fluid consumption

Auto/Manually adjustable

Cleaning pater consumption

Auto/Manually adjustable

Vision parameters

CCD FOV

10*8mm

Camera type

130 thousand CCD digital camera

Camera system

Lock up/down optic structure

Camera cycle time

300ms

Fiducial mark types

Standard fiducial mark shape

Round, square, diamond, cross

Pad and profile

Mark size

0.5-5mm

Mark number

Max. 4pcs

Stay away number

Max. 1pc

Machine parameter

Power source

AC 220 ±10%, 50/60Hz 2.2KW

Air pressure

4~6kgf/cm²

Air consumption

~5L/min

Operating temperature

-20°C~+45°C

Working invironment humidity

30%-60%

Machine dimension (without flower light)

1140(L)*1364(W)*1404(H)mm

Machine weight

Appr 900kg

Equipment load bearing requirements

650kg/m²

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky