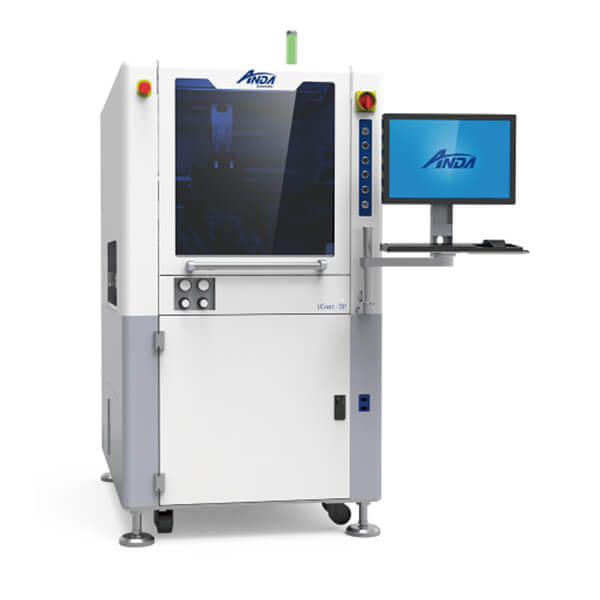

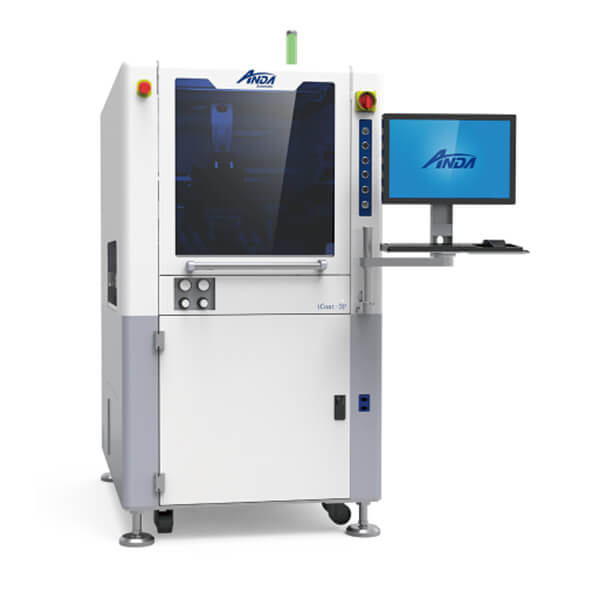

Anda iCoat-3P Mixer Dispense Machine

The ANDA iCoat-3P is an automated, robotic meter-mix machine that dispenses single or plural materials for a wide range of applications such as potting, encapsulation, dam & fill, bonding, sealing, molding, gasketing, thermal gap filler and reaction injection molding (RIM). iCoat-3P pairs with the MPS-230 two-component (2K) meter mix material preparation system for simultaneous material preparation and delivery.

The iCoat-3P meter-mix system is equipped with a three axes (X, Y, Z) 3D dispense motion gantry which integrates easily with inline automation processes or can be used offline for standalone batch applications. Designed for efficiency, the iCoat-3P improves manufacturing processes and eliminates waste material. The systems robust, steel welded frame ensures accuracy, repeatability, and long life. iCoat-3P supports project file transfer or use its onboard software for setting parameters, program teaching and project creation in real-time.

Standard Features & Benefits:

Dispense Single Component and Multi-Component Materials

Material Preparation Control System for Adjustable Mixing Ratio

Process Low Viscosity to Paste-like Reactive Resins

Three axes (X, Y, Z) 3D dispense motion system

Easy Operation and Quick Access Service Door/Panel Opening

Single Valve Configuration (Standard Machine Configuration)

LED UV Inspection Lamps

Printed Circuit Board (PCB) Conveyor Clamping

Uninterruptible Power Supply (UPS) & Voltage Stabilizer

Electrostatic Discharge (ESD) Grounding Point

CE Certified

Optional Features:

CCD Vision Camera

Barcode or 2D Code Scanning System

Variable Mixing Tube Size (< 300 mm)

Pallet Return Conveyor Underneath

MES Uploading System

iCoat-3P Specifications

| Motion System | |

| Gantry | Servo motors, ball screw drive |

| Gantry Axes | X,Y,Z |

| X-Travel | 360 mm (Standard) |

| Y-Travel | 450 mm (Standard) |

| Z-Travel | 100 mm |

| XY Maximum Speed | 800 mm/sec |

| XY Acceleration | 0.8 g with smooth control |

| XYZ Repeatability | ± 0.02 mm (20 µm) (± 0.0007") |

| Board Handling | |

| Work Area | X 360 × Y 450 × Z 100 mm |

| (X 14.17" × Y 17.71" × Z 3.93") | |

| Maximum Components Height | ± 90 mm (± 3.54") from PCB |

| PCB Edge Clearance | ≥ 5 mm (≥ 0.19") |

| Minimum Conveyor Width | 50 mm (1.95") |

| Max Standard Conveyor Width | 450 mm (18.11") |

| Process Flow (bidirectional) | L to R (Standard), R to L (Optional) |

| Chain Conveyor Weight Limit | 4 kg (9 lbs) [Standard], 10 kg (22 lbs) [Optional] |

| Conveyor Motor Power | DC 24 V 69 W × 2 |

| Conveyor Speed (XY) | 2 – 13 m/min (6.5 – 43 ft/min) |

| Conveyor Height | 900 ± 20 mm |

| (35.43" ± 0.79") | |

| Conveyor Width Adjustment | Automatic (motorized) |

| Operation Configuration | |

| Valve Configuration | Dual valves in a row (fixed width) |

| Dispense Valve Widths | 0.2 – 2 mm (0.0078" – 0.078") |

| Spray Valve Widths | 1.6 – 30 mm (0.06" – 1.2") |

| Maximum Speed | 800 mm/s |

| Repeatability | ± 0.02 mm (20 µm) (± 0.0007") |

| Facility | |

| Footprint | L 900 x W 1300 x H 1675 mm |

| (L 35.43" x W 51.18" x H 65.94") | |

| Weight | 560 kg (1235 lbs) |

| Air supply (dry, unlubricated air) | 0.4 MPa (60 psi, 4 Bar) |

| Exhaust Requirement | 15 m³/min (500 CFM) |

| Power | AC 220 V 50/60 Hz |

| Rated Power | 2.4 kW |

| Standards Compliance | SMEMA, IPC-CFX, CE |

| Interface | |

| Computer | PC + KMM |

| Software | Anda iCoat UI |

| OS | Windows 10 |

| Programming | File transfer, Onboard keyboard/mouse |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky