Axxon Mycronic MYC60 High-end automated assembly industrial dispenser

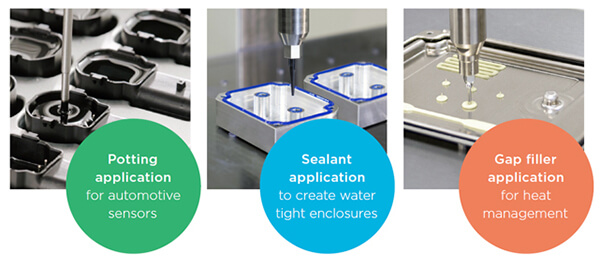

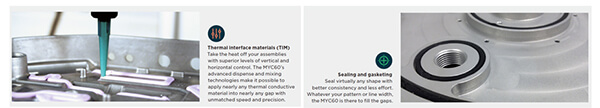

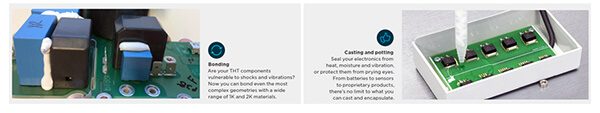

Applications such as potting, THT-bonding, gasketing and dispensing of thermal interface materials are some of the capabilities provided by MYC60

Product Features

As an industry leader in precision jetting, dispensing and coating solutions, Axxon Mycronic has long been at the forefront of industrial automation in electronics protection. The MYC60 takes these capabilities to a new level, giving manufacturers a versatile, customizable platform for high-volume dispensing of nearly any 1K or 2K material.

Whether you’re producing automotive assemblies, 5G infrastructure or aerospace electronics, the MYC60 offers an all-in-one solution for all your medium- to high-volume dispensing, positive displacement, progressive cavity and process control demands.

Inline or batch configurations. Complete with a wide range of conveyors, trolley and robotic integration options. Whatever your application is, the MYC60 offers the latest process controls together with the quality and flexibility Axxon Mycronic is known for.

MYC60 comes complete with a wide range of conveyors, trolley and robotic integration options for inline or batch configurations. Whatever the application, the MYC60 offers the latest process controls together with the quality and flexibility Axxon Mycronic is known for.

Specifications

MOTION SYSTEM

Z-axis repeatability

±25um@3σ

X-Y repeatability

±25um@3σ

X-Y acceleration

0.8 g peak

X-Y velocity

800 mm/s peak

Z travel

120mm. actual Z travel depends on valve and fluid reservoir configuration

Drive system

AC servo motor with precise ball screw

DISPENSING AREA

MYC60

1-part pumps: 650x500x120mm(XxYxZ)

2-part pumps (V): 450x400x120mm(XxYxZ)

MYC60 PRO

1-part pumps: 1,000x600x220mm(XxYxZ)

2-part pumps (V): 700x600x220mm(XxYxZ)

BOARD HANDLING

Max. top clearance

230 mm

Max. bottom clearance

130 mm

Load capacity

30kg with standard conveyor

FACILITIES REQUIREMENTS

System footprint MYC60(WxDxH)

1,831x1,310x1,880mm

VISION AND LIGHTING

Camera resolution

1.3M pixels

Field of view

14.0 x 11.0 mm

Lighting

Ring Light or Red/Green/White LEDs

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky