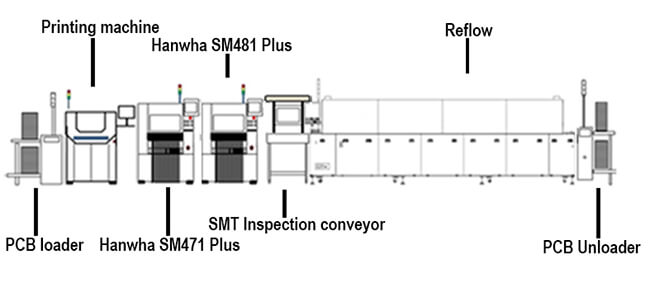

Hanwha SM471 Plus SM481 Plus SMT Full Automatic Assembly line

Hanwha SM471+SM481 Plus Assembly line configuration:

3.Hanwha SM471 Plus Pick and place machine

4.Hanwha SM481 Plus Pick and place machine

6.HELLER 1809 MK7 SMT Reflow Soldering Oven

Placement Speed: 118,000 CPH

Accuracy:±40um@μ±3σ

Feeder Capacity(8mm):120ea+120ea

Component Range:Fly: 0402 ~ □16mm / Fix(Opton): ~□55mm, L75mm Connector

PCB size(mm): L50*W40--L510*W460

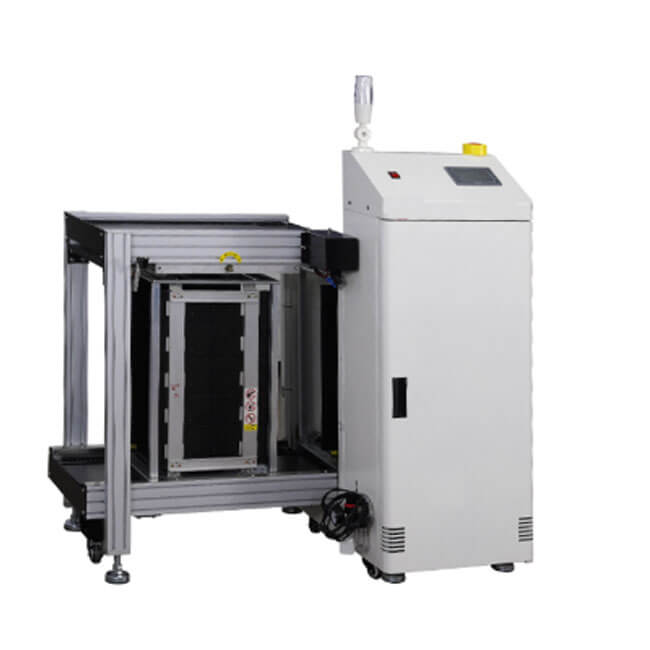

PCB frame loading machine is a kind of automatic loading equipment for electronic components PCB board. It is usually composed of a conveying system, a positioning system, and an upper plate manipulator.

The working principle is to place the PCB board and component material that need to be mounted on the board in the material frame, and send the material frame to the machine through the conveying system. Then, the positioning system is used to accurately locate the position of the PCB board, and then the components are removed from the material frame by the upper board manipulator and placed on the PCB board accurately.

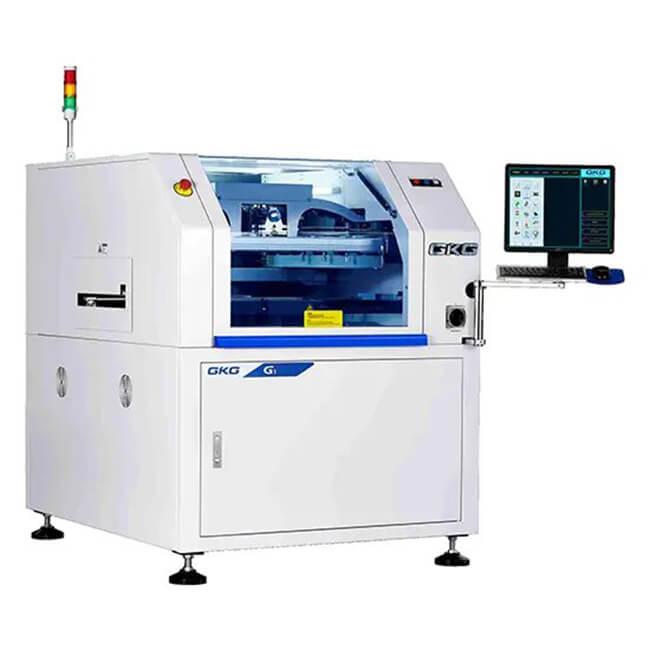

GKG G5 is a high-precision and high-stability fully automatic visual printing machine, high-resolution visual processing, high-precision transmission system, suspended automatic adaptive scraper, precise board positioning processing and smart screen frame clamping structure, compact structure , both accuracy and high flexibility, precise printing required functions.

1. GKG dedicated manual adjustment pre-lift platform: simple and reliable structure, low cost, convenient manual adjustment, can quickly realize the adjustment of the PIN pin jacking height of PCB boards with different thicknesses.

2. Image and optical path system: The uniform ring light and high-brightness coaxial light of the brand-new optical path system, together with the brightness function that can be adjusted steplessly, make all types of Mark points can be well recognized (including uneven ones) Mark point), suitable for tin-plated, copper-plated, gold-plated, HASL, FPC and other types of PCBs of different colors.

3. Scraper system: Slide rail type scraper system, which improves the running stability and long service life.

4. Cleaning system: The new type of wiping rubber strip ensures full contact with the stencil, increases the vacuum suction to ensure that the residual solder paste in the mesh is vigorously eliminated, and truly realizes the effective automatic cleaning function, three cleaning modes of dry and wet vacuum , the software can set the cleaning mode and cleaning paper length at will.

3. Hanwha SM471 Plus Pick and place machine

The Hanwha SM471 PLUS is a high performance chip shooter which applies two gantries equipped with 10 spindles per head as well as a new Fly Camera system.

Compared to the existing SM471 model, its placement speed is increased further to 78,000CPH, which is the highest in the world among chip shooters of the same class. In addition, it is basically applicable to components from 0402 (01005inch) chips to maximum □14mm IC components. Its actual productivity and placement quality is improved by applying high-speed and high precision electrical feeders. With two gantries and dual lane, the SM471PLUS supports various production modes to maximize the productivity of SM series machines.

4. Hanwha SM481 Plus Pick and place machine

Features: New flying head structure and optimization of suction/placement actions for 10 Spindles

• Highest placement speed in its real class

• Placement accuracy correction system (suction position correction, head correction, track correction, etc.)

• Can mount 0402~□16mm (H=10mm), for the production of long boards for LEDs and displays

• Compatible with MAX.740(L)×460(W) PCB (option)

• NEW The vacuum system and suction/placement mode are optimized, and the function of automatic alignment of the suction position

• Through the vacuum pump, the suction is stable and the consumption of air pressure is minimized

• Applicable to electric feeder, improving actual productivity and placement quality

• And it can be shared with SM pneumatic feeder to solve customer's convenience

• Parameters: Up to 120 8mm feeders (Docking Cart) can be accommodated

10 Shaft*1 Cantilever

• Mounting speed: 40,000CPH (excellent conditions)

• Mounting accuracy: ±50um@u+3ò/Chip, ±30um@u+3ò/QFP

• Component size: Chip 0402~ 16mm IC(H 10mm)

• Substrate size (single rail): 50(L)*40(W)~460(L)*400(W)

• PCB thickness: 0.38mm~4.2mm

• Power supply: AC200/208/220/240/380/415V(50/60Hz,3Phase)Max.4.7kva

• Air pressure: 0.5~0.7Mpa (5-7kgf/c㎡) 160nl/min

• Weight: about 1655KG

• Equipment size: 1650(L)*1680(D)*1530(H)

PCB Inspection conveyor machine provide secure and caring to handling printed circuit board involving SMT manufacturing. Inspection conveyor with light will be easier for operator to do inspection or test. We consider lots for producing our inspection conveyor products such as durability and reliability. So, our inspection conveyor machine will be suitable for small and big production systems. And also it can be highly customized with attractive price-performance ratio.

1.Modular design for inspection conveyor

2.Weighted design improves stability

3.More accurate with durable laser-cut stainless steel guide edge

4.Smooth and parallel width adjustment (screw)

5.Optional PCB detection mode

6.Customizable equipment length

7.Adjustable transport speed

8.SMEMA compatible

9.ESD belt

10.Motor drive

11.Highly sensitive “OMRON” photoelectric switch

12.Equipped with lights

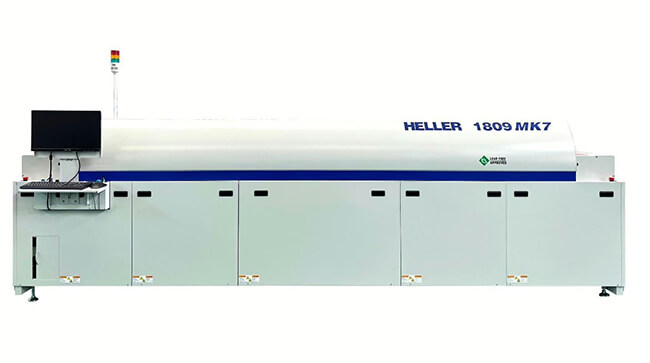

6. HELLER 1809 MK7 SMT Reflow Soldering Oven

The 1809 MK7 is a reflow oven with 9 heated zones and conveyor speeds of up to 1.88m/min suitable for medium and high volume applications. The 1809 offers reduced nitrogen and electrical consumption with it’s advanced energy management system, advanced flux management options, and the lowest delta T’s.

- Built-in Thermal Monitoring

- Nitrogen Capable to < 100 ppm

- Energy Management System

- Virtually No Maintenance

- 10” Wide Heater Modules

Appearance structure: sheet metal structure and aluminum profiles into the frame, surface spray treatment, color is white.

Microcomputer PLC control system, stable and reliable work.

Touch screen display operation, with automatic fault diagnosis function, man-machine dialogue is convenient.

Multiple sound, light and touch screen prompt alarm function.

The lifting step of the rack can be set according to the PCB thickness.

With automatic counting function, convenient production statistics.

Humanized design ensures that the PCB board is not broken and improves the output capacity

The bottom connection receiving PCB board uses a motor to feed the board to the material frame

Stepper motor push plate, the force can be adjusted, the speed can be set on the touch screen,

The push-plate device uses two end limits to protect the PCB board

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky